Which Fiber Termination Method is Right for You?

Filed under: General

Comments: Comments Off on Which Fiber Termination Method is Right for You?

When it comes to deploying fiber links in the data center and telecommunications rooms, there are several different options ranging from pre-terminated and fusion splice options, to field-terminated connectors. When it comes to choosing one of these methods, there are several factors to consider that can help you determine the best option for your specific scenario.

First and foremost, you need to consider the immediate applications and equipment interface requirements, as well as future scalability plans. For example, if you plan to deploy a high-speed parallel optics application like 100GBASE-SR4 or 200GBASE-SR4 that require multi-fiber MTP connectors, this may limit your termination method since MTPs are not available in all termination methods. While budget will always be a decision factor, you will also want to consider the number of connections, the project schedule, insertion loss performance, the level of expertise of those doing the installation and the overall environment where the installation will occur. With these factors in mind, let’s take a closer look at your options.

Pre-terminated Fiber Solutions

Available in multiple fiber types, counts and connector interfaces including Multimode and Singlemode fiber types and multi-fiber MTP, LC, SC, ST connector interfaces, Siemon’s Base 12 and Base 8 pre-terminated solutions feature pre-terminated cable assemblies that simply plug into modules or cassettes house within an enclosure. With low-loss options, MTP connectivity and hybrid MTP-to-duplex assemblies, these solutions readily support high-speed parallel optic and breakout applications.

Because they are 100% factory-terminated and tested with a plug-and-play deployment, pre-terminated solutions require no fiber termination skills and result in less variability and superior performance. They are also considered a greener option due to less packaging, consumables and onsite waste. Pre-terminated solutions are preferred for high-density, large installations as they save pathway space and allow for quickly terminating large fiber counts. While these solutions do cost more in material and are made to order, if lengths can be carefully planned, the labor savings and faster deployment time can outweigh any material premium. In fact, these solutions can be deployed up to 90% faster. However, they may not be the most cost effective in low fiber count duplex applications, and they are not well suited for disaster recovery or other quick turn-around deployments due to planning and longer lead times.

Splice-On Pigtails

Siemon’s splice-on pigtails are available in Multimode and Singlemode and various connector types, including duplex and simplex LC, SC and multifiber MTP. Splice-on pigtails feature a short fiber stub that protrudes from a pre-polished connector and is fusion spliced to the incoming fiber using an electric arc. This process requires a fusion splicing machine that aligns two cleaved fibers and fuses them together. There are also mass fusion splicers that fuse 12-fibers in a ribbon cable at once.

Splice-on pigtails offer a strong, low-loss connection, typically around 0.1dB, with the least amount of reflectance. These solutions are ideal for transitioning from 250µm OSP to 900µm indoor cable, which is why you see them used a lot in entrance facilities for incoming fiber – especially in cloud and colocation data centers where there is fiber coming in from various service providers. They also don’t have a lot of onsite waste, cost less than pre-terminated solutions from a material standpoint, and they offer the benefit of not needing to plan exact lengths or deal with longer lead times.

However, splicing can be expensive for anyone who doesn’t own a splice machine – although renting a splicing machine is an option. There is also the added cost and space required for the splice trays and sleeves to house and protect the splices. The performance of these solutions is also highly dependent on the quality of the cleave so a high-quality cleaver is recommended. From labor standpoint, the fusion process does require more time compared to pre-terminated solutions, and you need to have a decent workspace to accommodate the process.

Splice-On Connectors

Pre-polished fusion splice-on connectors like Siemon’s OptiFuse™ are available in Multimode and Singlemode and with LC or SC simplex connectors. Instead of splicing to a pigtail stub, with splice-on connectors, the stub resides inside the connector. The stub is fusion spliced, and the connector parts are assembled around the ferrule.

Like splice-on pigtails, splice-on connectors offer a strong, low-loss connection without the need to predetermine lengths and require a fusion splicing machine and a quality cleave. Splice-on connectors can terminate 250µm coated fiber, 900µm tight buffered fiber and 900µm breakout kits. However, with splice-on connectors there is no need for splice trays and protective splice sleeves since the splice is protected within the connector housing itself. This reduces material requirements, conserves space within fiber enclosures and can save up to 30% on installation time compared to pigtails.

Field-Terminated Connectors

For field-terminated connectors that do not require splicing, there are generally two options-epoxy/polish connectors like Siemon’s LightSpeed™ connectors which are available in SC, LC and ST in both Multimode and Singlemode and mechanical splice connectors like Siemon’s LightBow™ connectors, which are available in SC and LC in both Multimode and Singlemode. While not ideal for ultra-high density installations or very tight insertion loss budgets that require less than 0.2dB insertion loss per connector, field-terminated connectors are perfect for lower fiber counts, repairs and reconfigurations-especially for situations where installers do not have the luxury of planning and lead times associated with pre-terminated solutions or do not own an expensive fusion splicer as required for splice-on pigtails or splice-on connectors.

Epoxy/polish connectors use epoxy to join the fiber and the connector ferrule, and the epoxy is then cured. The protruding fiber must be cleaved and polished to ensure smooth flush finish before connecting. While many experienced fiber technicians may prefer epoxy/polish connectors, they are not the best option if there is a limited skill set-their average insertion loss is about 0.2 – 0.3dB for those who are experienced but could be much higher for those who are not. Because the end face is exposed and polished in the field, care also needs to be taken to prevent contamination. Epoxy/polish connectors require the most consumables and results in the most waste of all the fiber termination options.

Mechanical splice connectors where two fibers are joined in an alignment fixture using index matching gel have become a more popular field-terminated connector option as they offer faster termination with no cure time, are not difficult to terminate and offer limited waste with less consumables compared to epoxy/polish connectors. When selecting a mechanical splice connector system, consider that Siemon’s LightBow system features a low-cost termination tool with no power or batteries required that can terminate a connector in less than one minute, which is not the case with all manufacturers’ mechanical connector systems. There is also a lower risk of contamination for solutions like LightBow where the dust cap can be left on during the termination process.

We Can Help You Choose

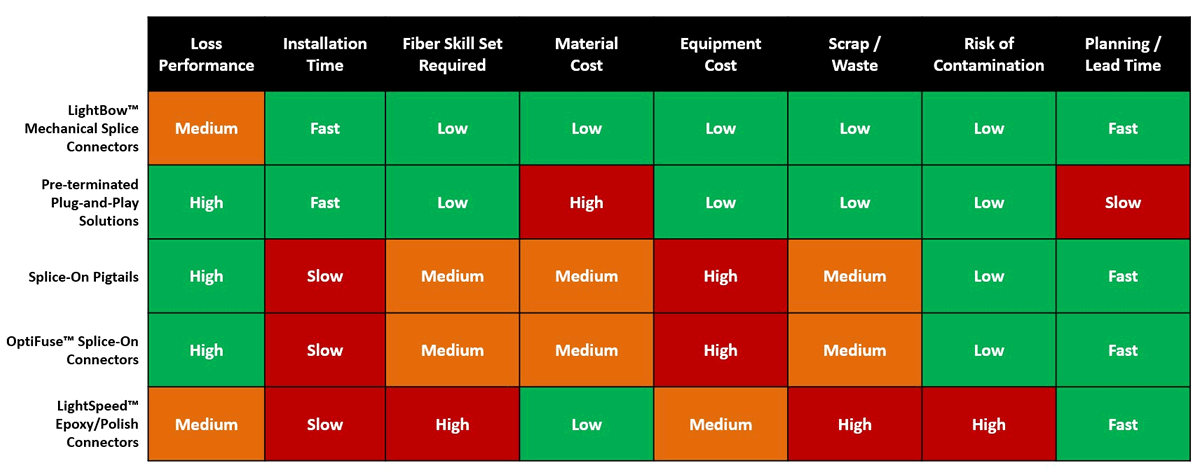

To better help you select a fiber termination method, we’ve put together the following summary chart. Our superior technical support is also always available to discuss your options and determine the best solution for your specific situation and budget. The good news is that no matter which solution ends up being right for you, Siemon offers ALL the options as part of our Advanced Fiber Solutions.