Siemon’s Value Vertical Cable Manager – Day 2 Considerations

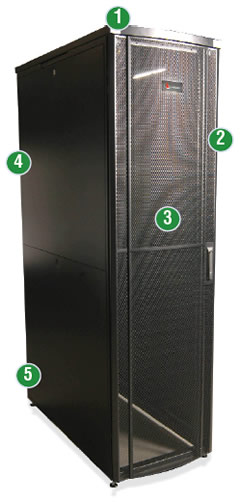

When Siemon developed its new Value Vertical Cable Manager (VVCM) system, most of its features and capabilities were based on input from a wide range of company types and job roles among channel partners, end-user customers, consultants and system integrators. For the contractors and integrators tasked with installing racks and cable management on the jobsite, the focus was all about user-friendly features to enable faster, more efficient Day 1 deployments, and that input resulted in key VVCM innovations:

- Small, light modular design and packaging that is easier to store, transport, and move around the jobsite versus heavy, single-piece traditional 7-foot vertical managers.

- Intuitive, tool-less assembly process that takes less than 5 minutes start-to-finish (check out a time-lapse assembly video here.)

- Dual-hinged doors with spring-loaded “finger-operated” latches vs. snap on covers.

While those Day 1 VVCM features were also valued by end-users and consultants, the overall user/consultant demographic placed a higher premium and interest on Day 2 benefits. That is a logical outcome, as once the contractor has wrapped up the initial install, it is typically the end-users that are left to manage the ongoing moves, adds and changes to that beautifully installed cabling infrastructure. Day 2 is all about accessibility, scalability, and flexibility.

In terms of accessibility, the biggest challenge with most lower-cost vertical managers is the covers. These tend to be snap-on style plates that, while they can be removed to provide more or less unhindered access to the cable management space, are difficult to reattach properly. In fact, it isn’t uncommon to see snap-on covers left aside and not re-attached at all, which not only exposes the cabling pathways to potential disruption, it detracts from the space’s aesthetics.

Based on customer feedback, the VVCM was designed with proper doors. These doors are dual hinged so that they can be opened in either direction, providing excellent access regardless of the cable routing configuration or surrounding space challenges without the consistent need to remove the doors completely. However, if users prefer to remove the doors, the spring-release clips at each corner and easy-to-identify attachment points make re-attachment a quick and simple process.

Scalability should also be considered – and when thinking about cable managers, scalability equals room to grow. Like most vertical cable managers, the VVCM is available in a range of widths – the wider the manager, the more management space it provides. Choosing the best manager size for the application requires some pre-Day 1 foresight based on per rack equipment and patching field density, horizontal cabling density, and future expansions. As a general rule of thumb, it is far safer to go bigger than initial estimates if at all possible.

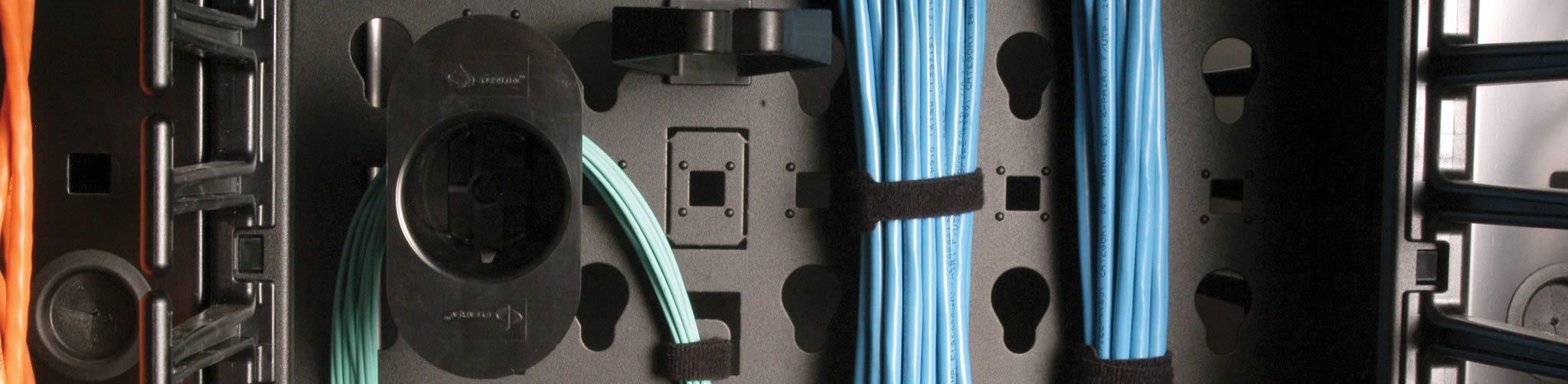

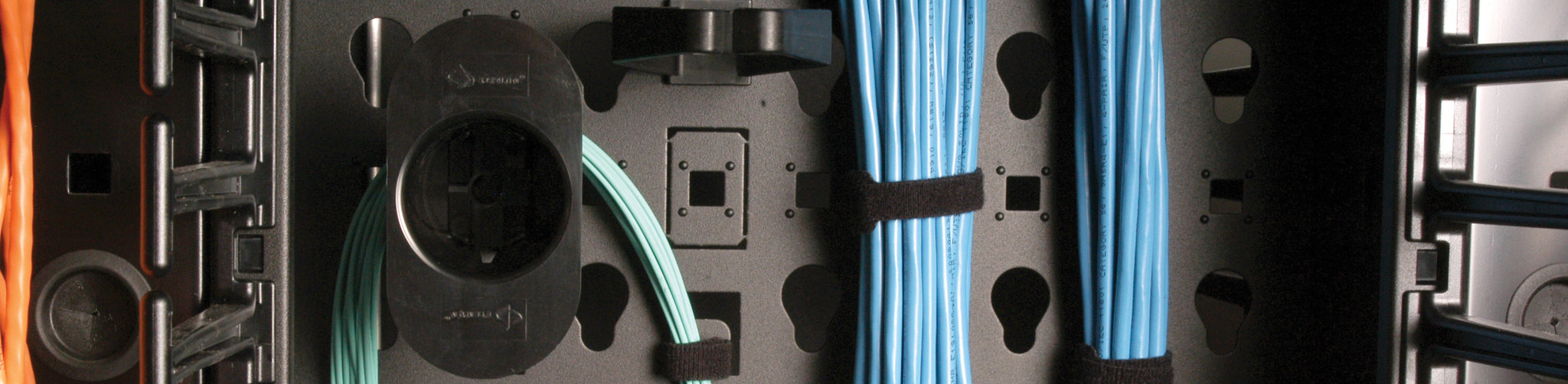

Once the system is installed, that extra management space will also make basic day-to-day maintenance easier by virtue of providing more room to work. Ongoing MAC work can be further simplified with well though-out, high-capacity cable and cord routing support, and the VVCMs cable management “fingers” were expressly designed to provide that support. Each finger opening aligns with the rack’s mounting spaces and can accommodate up to 48 Category 6A cables, providing a direct and orderly path from the rack-mounted equipment or patching ports to the vertical cable management space.

As cabling channels are re-routed, new channels are added, and additional equipment such as PDUs need to be deployed Day 2, the flexibility to reconfigure the cable management space becomes a key consideration. While most value-level vertical managers provide limited, static space for cabling support accessories such as cable ties, the VVCM’s rear divider plates offer an almost countless number of potential configurations. The plates feature integrated attachment points for cable tie-downs, ¼ turn cable management accessories, and fiber spools, as well as standard PDU mounting points, allowing the managers to support power cable management in addition to network cabling. The divider plates are custom mountable, allowing users to put management support where it is needed, and are reversible to provide more pathway space to either the front or back of the rack as needed.

These Day 2 considerations should be top of mind in a user’s cable management selection regardless of which solutions are on the short list, but a complete analysis must include costs. In the past, the market primarily offered lower-cost bare-bones options or feature rich premium solutions, with a significant cost delta between basic and premium options and little or no middle-ground options. The VVCM was specifically developed to fill that market gap. Combined with Siemon’s 2-Post Value Rack and RouteIT Horizontal Cable Managers, the VVCM completes an integrated rack and cable management solution that is both cost-competitive with basic options, yet offering enhanced features typically limited to more expensive premium systems.

In a traditional network infrastructure, horizontal cables terminate to work area outlets, with equipment connections made via double-ended patch cords. While this configuration is very commonly used is intelligent buildings to connect IP devices such as

In a traditional network infrastructure, horizontal cables terminate to work area outlets, with equipment connections made via double-ended patch cords. While this configuration is very commonly used is intelligent buildings to connect IP devices such as