What To Consider Before Hitting the Road to 400/800G

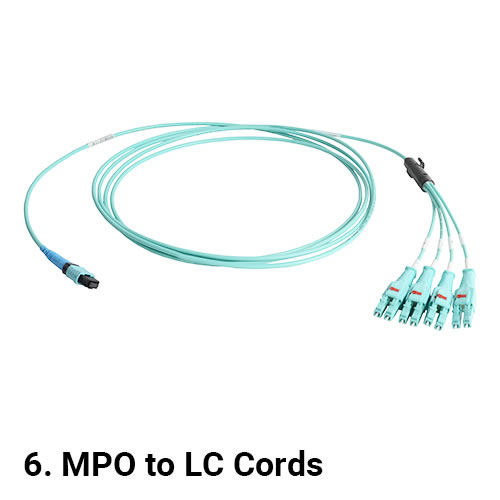

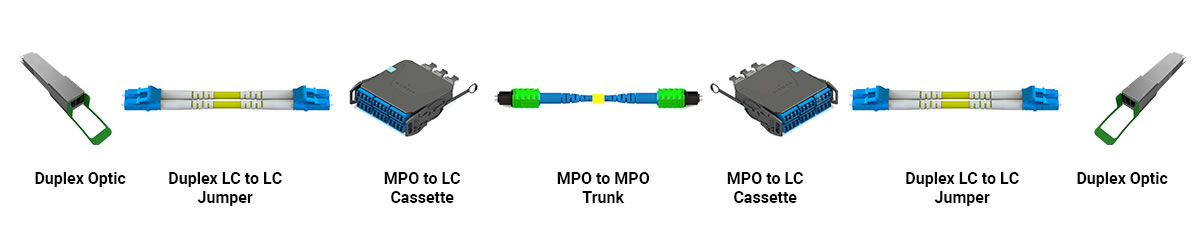

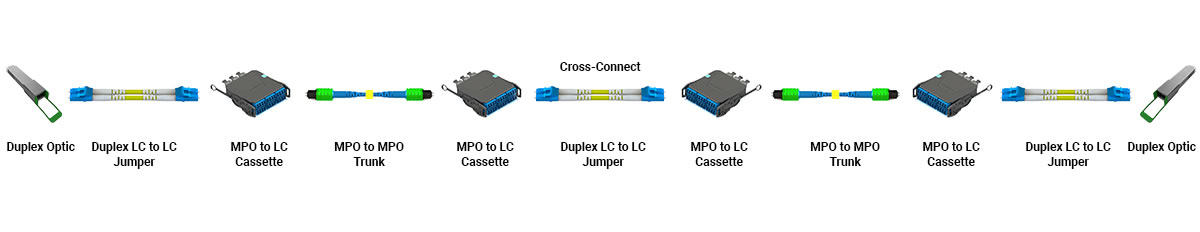

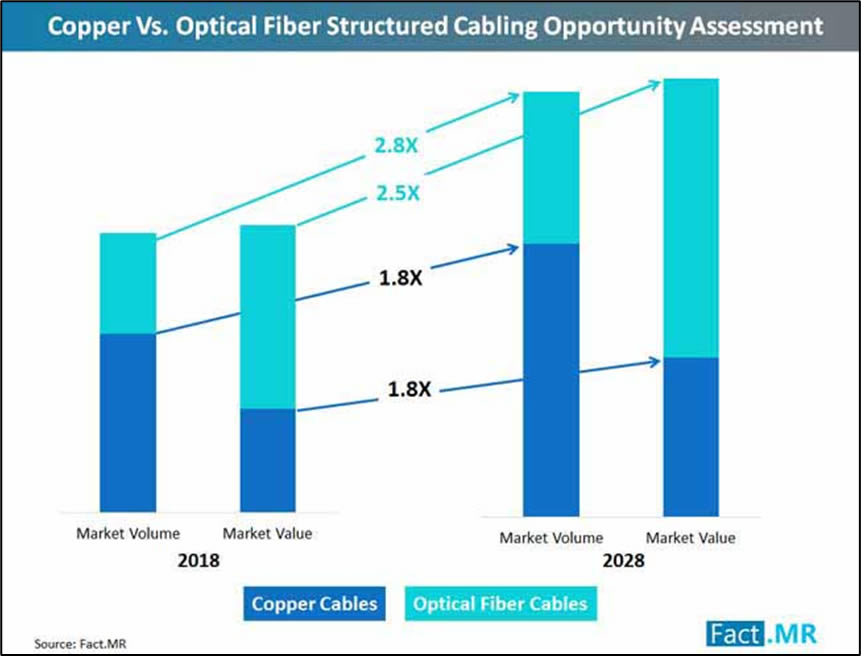

Our own Gary Bernstein makes a lot of sense in his tech brief entitled “The Road to 400/800G is Paved!” As he points out, enterprise data centers are currently running 1G or 10G server speeds and 10G or 40G uplink speeds and are looking at migration paths for 25G or 50G for servers and 100G or 400G for uplinks. Perhaps a step further ahead, cloud data centers currently at 10G to 25G for servers and 40G or 100G for uplinks are actively eyeing server speeds to 50G or 100G with 200G or 400G uplinks. I encourage you to read Gary’s brief to get the full background detail, but the bottom line from a fiber cabling standpoint is that Base-8 fiber topologies leveraging MTP connectivity is the best solution to ease migration to 400G, 800G and beyond. In other words, Base-8 fiber paves the road to future speeds.

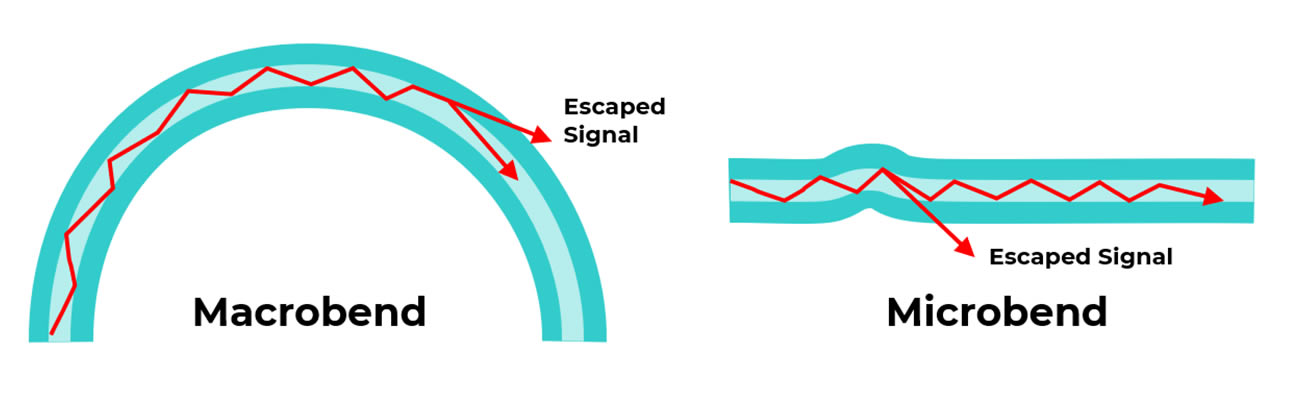

But there are considerations and choices to be made before you even leave the garage. You need to consider your current needs. The most efficient fiber cabling and connectivity infrastructure design to support the 10G server and uplink speeds you need right now will not be exactly the same as what you will need to run 100G server speeds and 400G uplinks down the road. You can make migration easier by installing high-performance, Ultra Low Loss OM4 multimode and singlemode fiber and leveraging Base-8 MTP assemblies wherever practical, but ultimately there’s a good chance that you will need to modify your connectivity when the time comes to trade up to higher speeds.

With a bit of planning while still “in the garage”, you can handle those eventual connectivity reworks without having to tear out half of your fiber infrastructure. The key piece here is the physical fiber connectivity support system – specifically the fiber enclosures and panels.

For example: Right now, traditional fusion-splice LC duplex connectivity might be the most efficient, cost-effective solution for your 10G channels, so you select a fiber enclosure well suited to fusion splicing. Will that enclosure be capable of supporting higher-speed connectivity like Base-8 MTP modules or adapters when the time comes to upgrade? If the answer is no, then that enclosure will eventually need to be ripped out and replaced – a disruptive and expensive prospect that, hopefully, you would like to avoid.

If your initial answer is yes, then ask yourself if that enclosure will make your upgrade easy. What compromises might you need to accept in converting an enclosure best suited to fusion to support MTP plug and play? This is the time consider the physical elements like mounting provisions for modules and adapters, configurable cable management, high-volume cord routing, and bend radius control – can I easily reconfigure the enclosure to adapt to my next generation of connectivity? Just as importantly, does it provide the accessibility to make moves, adds, and changes without disrupting your surrounding infrastructure?

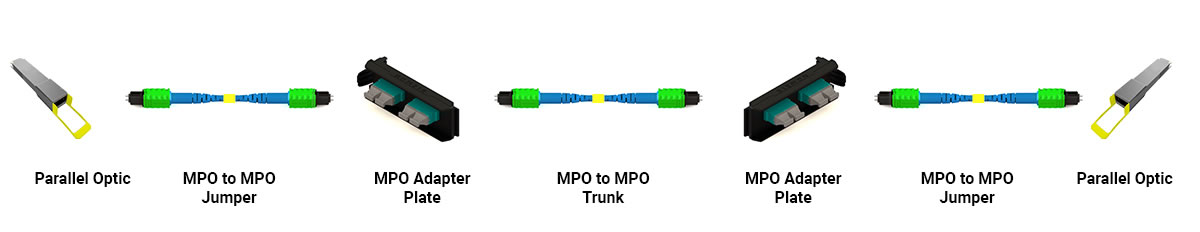

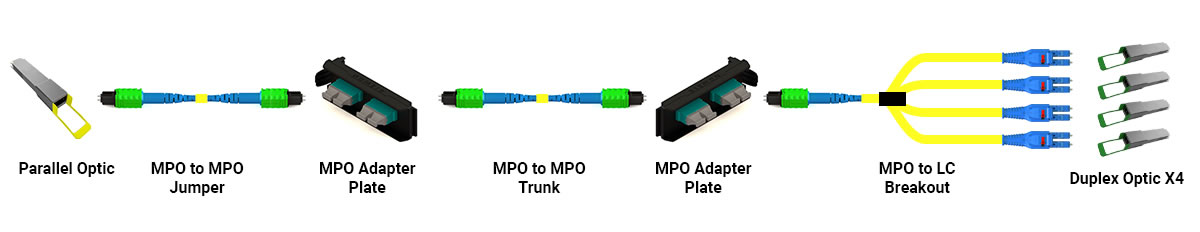

The first piece of good news here is that by even including physical fiber connectivity support infrastructure like enclosures in your future upgrade considerations, you are ahead of the game. The second is that there are highly adaptable, scalable fiber enclosures available. Siemon’s new LightVerse® platform, for example, offers a core set of enclosures all capable of supporting traditional splice trays, pre-terminated splice cassettes, MTP-to-LC duplex plug and play modules, LC duplex adapters, and MTP-to-MTP pass-through adapters. Paired with highly customizable cable and cord management options, these configurations can be easily modified to fit each unique migration path – even in mix and match situations. Add in the enhanced accessibility of front and rear sliding trays/drawers and a removeable cover you will find that your future connectivity upgrades can be done more or less on the fly.

To learn more about LightVerse’s innovative, flexible approach to connecting your current and future fiber cabling needs, visit: LightVerse®