Home

The global data center market is poised for substantial growth, projected to surge by over 6% year-over-year throughout this decade. This robust expansion is fueled by key technologies such as artificial intelligence (AI), internet streaming, and gaming, shaping the digital landscape in profound ways. Amidst this accelerating growth, data centers are evolving into sophisticated hubs, increasingly automated and equipped to handle diverse applications and a myriad of compute and storage devices, effectively managing the escalating

Optical Network Tapping

Category: Fiber

Optical Network Tapping, also known as packet tapping or network monitoring, is a technique used to verify the performance and integrity of data streams as they flow between different devices on a network. This practice is often employed in data networks for various purposes, including network troubleshooting, security analysis, performance monitoring, and data collection. In this blog post, you will learn about the different types of network tapping, the most common optical split ratios, what

The Benefits of Mixing Copper and Fiber in Data Centers and Intelligent Buildings

Category: Data Center, Fiber, Intelligent Buildings

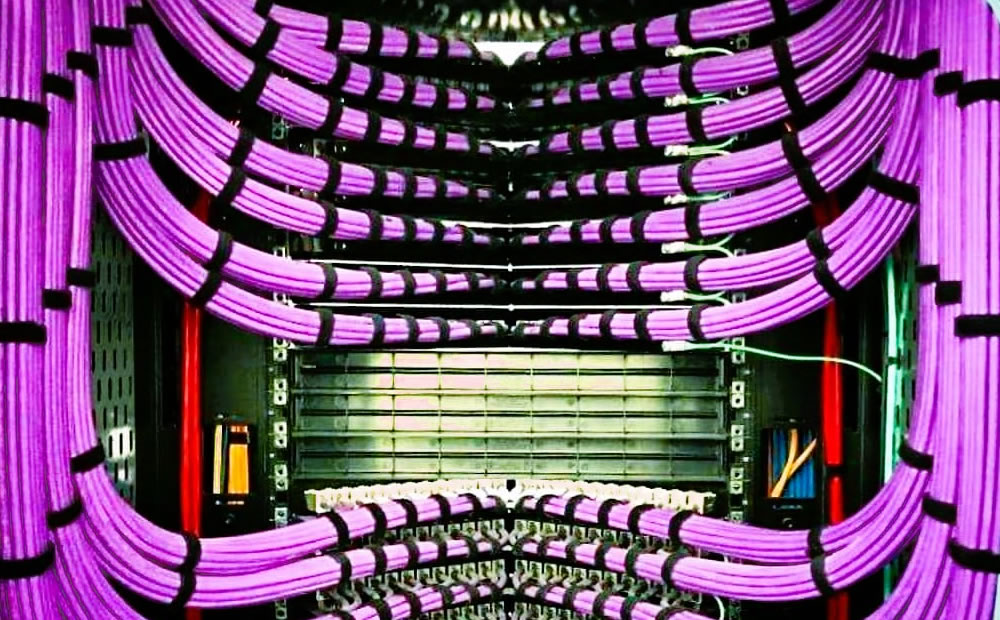

In the world of data centers (DC) and Intelligent Buildings (IB), copper and fiber cabling are widely recognized as the primary media types for network connectivity. The ability to seamlessly integrate these two types of cabling offers a multitude of installation options to address various cabling applications, network topologies, and equipment connectivity requirements. In this blog post, we will delve into the challenges faced by network engineers when dealing with the integration of copper and

Optical fibre has become the cabling media of choice in new data centre deployments whilst existing facilities’ fiber continues to replace copper cables. It is because fibre offers greater flexibility, scalability, and bandwidth capabilities to support the ever-increasing volume of data. At the same time, the number of optical fibre links between switches, storage area networks (SANs) and equipment continues to grow to support new data centre architectures. With the volume of fiber increasing and

Base-16 is an MPO plug and play cabling system that utilizes an MPO-16 connector vs. the MPO-12 connector that is used for more commonly in Base-8 or Base-12 cabling systems. The MPO-16 connector has specifications that are defined in TIA-604-18 released in 2018 and IEC 61754-7-1 released in 2014, but the connector has seen limited market adoption. With the recent introduction and promotion of Base-16 systems by some manufacturers, the time is right to share