Do I Need an LP-Rated Cable?

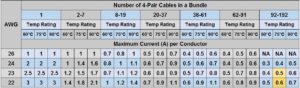

The 2017 edition of the NFPA 70® National Electrical Code® (NEC) contains a new Article 840, Part VI requirement addressing premise powering of communications equipment over communications cable. This requirement only applies when the power supplied is greater than 60W (e.g., it does not apply to IEEE 802.3 Type 1 (15W), Type 2 (30W), and Type 3 (60W) PoE implementations). In this case, the maximum ampacity that may be carried by a cable conductor is determined by the conductor gage (AWG) size, number of 4-pair cables in a bundle, and the mechanical temperature rating of the cable as provided in Table 725.144 of the NEC and excerpted below. Note that this table is based on an ambient temperature of 30° C (86° F).

As an example, the maximum ampacity of one 24 AWG category 5e conductor, mechanically rated to 60° C and contained within a bundle of 62-91 cables, is 400 mA (800 mA per pair). Since the developing IEEE P802.3bt Type 4 90W application is targeting an operating current of 960mA per pair, this example product and installation configuration would not be compliant to the NEC requirements for support of this application. To overcome this restriction, the NEC provides a provision to use a limited power or LP-rated cable jacket to support increased ampacity. Another alternative allowed by the NEC is to use cables having larger diameter conductors and/or a higher temperature rating to reach the desired ampacity capability.

Siemon recommends the use of its shielded category 6A and category 7A cables (having 23 AWG and 22 AWG sized conductors, respectively) for support of 60W and higher power applications because these cables offer the same application support capability as LP-rated cables with the added benefits of greater heat dissipation, power efficiency, bandwidth, and noise immunity. Note that these cables are mechanically rated to 75° C (167° F) and, according to the NEC table (refer to the cells highlighted in yellow), are suitable for support of at least 500 mA per conductor/ 1 A per pair current levels in bundle configurations of up to 192 cables in 30° C (86° F) ambient temperature environments. Siemon has developed bundling recommendations for a much broader range of ambient temperatures. Following these bundling guidelines ensures that an LP-rated cable is not required to support greater than 60W applications within the environments for which Siemon cables are rated.