Safety First! Know Your Cable Jacket Ratings

In everything you do in life, “safety first” should be top of mind. This holds true in personal events and in the workplace – whether you put on a helmet before riding a bike or safety glasses when working with optical fiber. The same practice applies to specifying and installing the right cable for the right environment. That is why the NFPA-70 National Electric Code® (NEC) created different cable jacket ratings.

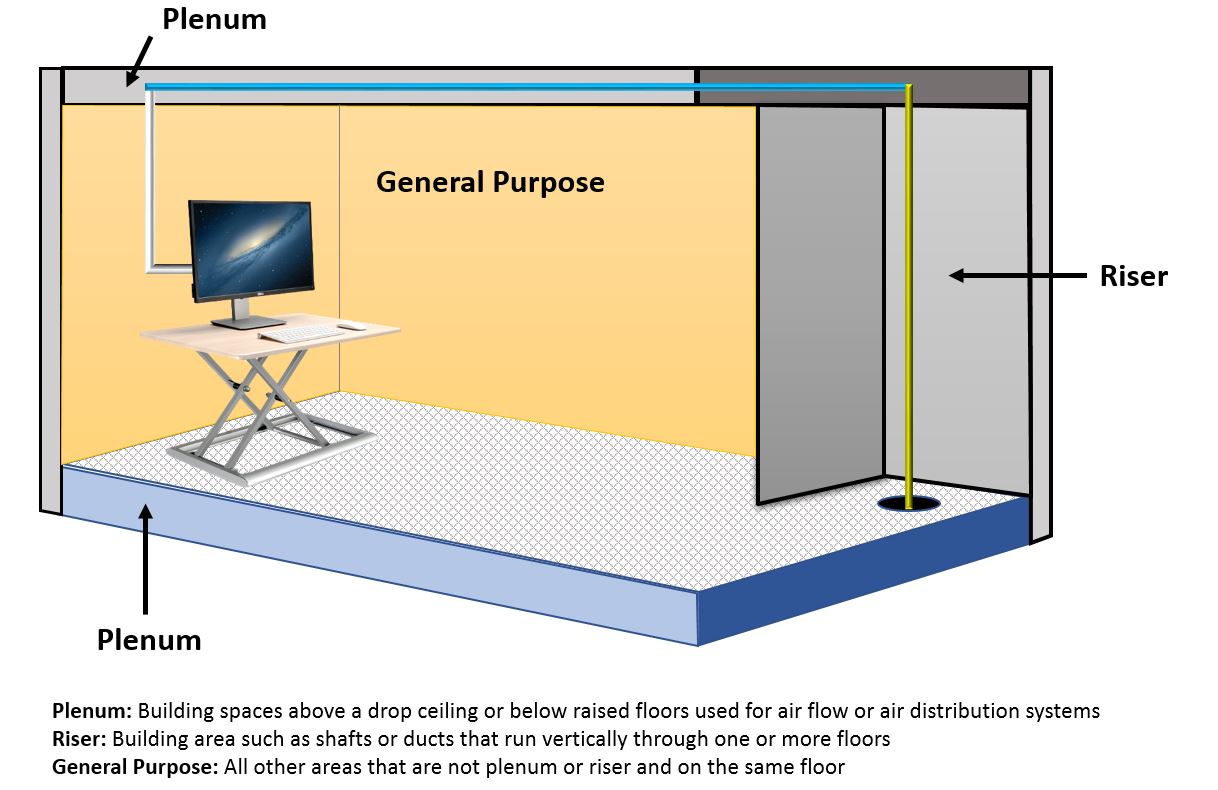

The primary purpose of the NEC is to prevent fires and to promote safety for humans and equipment. Communication cables face varied types of environmental stresses within the different areas of a building. The NEC is intended to minimize the risk of fire and the production of smoke and toxic fumes in each of those areas through the use of different types of cables and pathways. Fire, smoke and fumes can spread in two directions – vertically between floors, known as risers, and horizontally above the ceilings or below the floor where the building’s airducts are connected for heating and air conditioning, otherwise known as plenum spaces. See the simplified illustration of the different areas of cable runs.

Top Ratings

Both copper and optical fiber communications cable have jacket ratings to indicate the approved physical locations in which they are run. There are actually 16 ratings for conductive and non-conductive communication cables, but for this article we are only concerned with the most common in our industry. The three basic ratings for both cable types are general purpose, riser and plenum rated. Copper jacketing ratings are identified as CM/CMG (General use), CMR (Communications Riser) or CMP (Communications Plenum).

- The NEC defines CMP as being listed as suitable for use in ducts, plenums, and other spaces used for environmental air and shall also be listed as having adequate fire-resistant and low smoke-producing characteristics.

- The NEC defines CMR as being listed as suitable for use in a vertical run in a shaft or from floor to floor and shall also be listed as having fire-resistant characteristics capable of preventing the carrying of fire from floor to floor.

- The NEC defines CM/CMG as being listed as suitable for general-purpose communications use, with the exception of risers and plenums, and shall also be listed as being resistant to the spread of fire.

Fiber cable jacket ratings are similar to copper but designated OFN/OFNG (Optical Fiber Non-conductive General Purpose), OFNR (Optical Fiber Non-conductive Riser) or OFNP (Optical Fiber Non-Conductive Plenum). (Note: When copper is added to a fiber cable, such as armored constructions, it adds an electrical conductivity element to the cable and will be rated OFC/OFCG, OFCR and OFCP)

In the U.S., the NEC specifies the environment where each cable is best suited. Cable ratings are based on flammability testing to meet either required NFPA or UL specifications. Most cable manufacturers have their cables tested to these specs in national recognized labs. Note that a more stringently rated cable can be substituted for a less stringently rated cable, but not the reverse.

What about LSOH?

Low Smoke Zero Halogen cables, referred to as LSOH or LSZH, are commonly used in different parts of the world. However, the NEC does not recognize LSOH cables and they are tested to different criteria than CM/CMG, CMR and CMP cables. Make sure that the cable jacket to be installed always meets the requirements specified by the electrical code that applies to your country or location. Note that there are some jacket constructions that carry dual ratings, such as CM/LSOH. This is common for patch cords where having a dual jacket allows for use in a wider range of markets.

Bottom Line

What does this all mean and why should you be concerned? Basically, matching the right cable to the environment will minimize the hazards of fire, smoke and toxicity. When creating bids or bills of materials (BOMs), installers need to make sure that they are specifying the right cable for the job – both in performance and in safety. Before completion, building inspectors will check to make sure that all wiring meets local and state codes before signing off on any work. If not, the end user will not qualify for an occupancy permit. When standards and codes are not followed, it affects everyone. We take pride at providing our customers the best in quality and in safety. And if ever in doubt – ask your regional Siemon Technical Service Group!

Siemon’s Category 6 UTP cable comes in plenum, riser and LSOH, as well as outside plant variations and even CPR compliant versions for the European market. To check out Siemon’s full line of copper and fiber cables available in a wide range of ratings, visit the cable section of our product e-catalog.